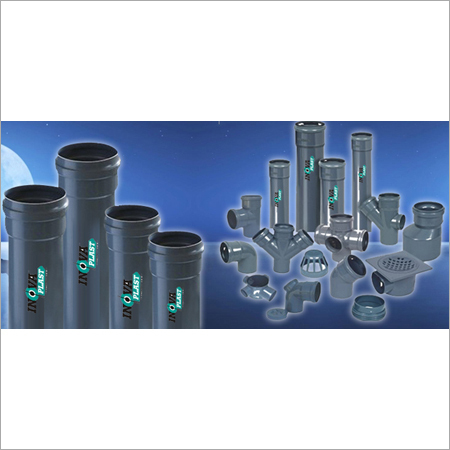

Industrial SWR Pipe Fittings

MOQ : 4.5 Tons

Industrial SWR Pipe Fittings Specification

- Material

- uPVC (Unplasticized Polyvinyl Chloride)

- Shape

- Round

- Standard

- IS 13592 / IS 14735 compliant

- Working Presssure

- 0.41 MPa (4.1 kg/cm) or as specified

- Working Temperature

- Up to 60C (intermittent)

- Connection

- Socketed/Push-fit

- Technique

- Injection Moulded / Extruded

- Size

- 75mm, 90mm, 110mm, 160mm (various sizes available)

- Thickness

- As per IS Standards; ranges from 2.0 mm to 4.0 mm depending on size

- Length

- 3m, 6m or as required

- Color

- Grey

- Surface Finish

- Smooth Finish for Low Friction Losses

- End Type

- Socketed, Plain, Spigot

- Durability

- Long Life, Non-corrosive, Rust-proof

- Leakage Proof

- Yes, with Rubber Ring Sealing

- Weight

- Lightweight for Convenient Handling

- UV Resistance

- Yes, suitable for outdoor installations

- Application

- Sewerage, Drainage, Rainwater and Wastewater Systems

- Installation

- Easy to Install, Maintenance Free

- Chemical Resistance

- High Resistance to Acids, Alkalis and Salts

Industrial SWR Pipe Fittings Trade Information

- Minimum Order Quantity

- 4.5 Tons

- Delivery Time

- 2-3 Days

- Main Domestic Market

- All India

- Certifications

- ISO

About Industrial SWR Pipe Fittings

Our firm is a coveted manufacturer, supplier and trader of SWR Pipe Fittings, that are made by combining Upvc wax with chemicals like lubricants, bentzotriazole, processing aids, heat stabilizers, phosphite based U.V stabilizers, carbon black and pigments UV stabilizers that avoids the loss of strength, imbritflement, yellowing and increase the light stability of Upvc. Moreover, these fittings are adored by clients for sturdy structure, easy installation, less maintenance and budget friendly prices.

Properties

ADVANTAGES

Product Range

Properties

- Hozen williams Coefficient : 150 remains constant.

- Dourometer hardness : 80 (as per ASTM-D-1785).

- Water adsorption in 24 hours : 0.01%

- Flammability : will not support combustion self extinguishing

- Maximum bending stress : 21 kgf/cm2

- Specific Gravity : 1.4 to 1.43

- Compressive : 450-560 kgf/cm2

- Tensile strength : 600-700 kgf/cm2

- Flexural strength : 650-700 kgf/cm2

- Vicat softening point > 80

ADVANTAGES

- Simple installation: Due to light in weight these pipes are easy to install and less time consuming than cast iron or Cement pipes.

- High Chemical Resistance: Highly resistant to acid, alkalies, cement, lime, oils and domestic affluents.

- Free Flow: Due to it's smooth inside surface any liquid flows very freely.

- Durable: These are strong and durable because of weather and sunlight resistant.

- These are also unaffected by termite, bacteria and fungus..

Product Range

- Available in sizes of outer Dia 63 mm to 315 mm in pressure rating of 2.5 kg/cm, 4 kg/cm, 6 kg/cm, 8 kg/cm, 10 kg/cm, 12.5 kg/cm

- Specifications

- Conforming to IS:4985:2000 with rubber ring joint as per ISO 4422 or DIN 8062 or IS:5382-85

| NOMINAL OUTSIDE | MEAN OUTSIDE | WALL THICKNESS | ||||

| DIAMETER | DIMATERE | TYPE A | TYPE - B | |||

| MAX | MIN | MAX | MIN | MAX | MIN | MAX |

| 40 | 40.0 | 40.3 | 1.8 | 2.2 | 3.2 | 3.8 |

| 50 | 50.0 | 50.3 | 1.8 | 2.2 | 3.2 | 3.8 |

| 63 | 63 | 63.3 | 1.8 | 2.2 | 3.2 | 3.8 |

| 75 | 75 | 75.3 | 1.8 | 2.2 | 3.2 | 3.8 |

| 90 | 90 | 90.3 | 1.9 | 2.3 | 3.2 | 3.8 |

| 110 | 110 | 110.4 | 2.2 | 2.7 | 3.2 | 3.8 |

| 125 | 125 | 125.4 | 2.5 | 3.0 | 3.2 | 3.8 |

| 140 | 140 | 140.5 | 2.9 | 3.4 | 3.6 | 4.2 |

| 160 | 160 | 160.5 | 3.2 | 3.8 | 4.0 | 4.6 |

Applications and Versatility

These SWR pipe fittings are developed for efficient management of sewerage, drainage, rainwater, and wastewater systems in residential, commercial, and industrial settings. Their robust construction and resistance to chemicals and UV light make them highly adaptable for outdoor environments.

Superior Material and Design

Manufactured from high-quality unplasticized PVC (uPVC), these fittings feature a smooth internal surface for low friction loss, superior leakage-proof sealing with rubber rings, and a socketed/spigot configuration. Their round shape and grey color offer a universal fitment and discreet appearance.

Ease of Handling and Installation

Lightweight yet durable, these pipe fittings are easy to transport, handle, and install using push-fit or socketed connections. Their user-friendly design allows for fast assembly, minimizing downtime and installation costs while offering long service life.

FAQs of Industrial SWR Pipe Fittings:

Q: How are Industrial SWR Pipe Fittings installed?

A: Industrial SWR Pipe Fittings are installed using socketed or push-fit connections with rubber ring sealing. The process is straightforward, requiring no special tools, enabling quick assembly and reducing labor time.Q: What makes these SWR pipe fittings suitable for chemical waste applications?

A: These fittings are manufactured with high-quality uPVC that provides excellent resistance to acids, alkalis, and salts, making them ideal for chemical waste management in various industrial and commercial environments.Q: When should SWR pipe fittings be used in sewerage and drainage systems?

A: SWR pipe fittings should be used when installing or upgrading sewerage, drainage, or rainwater management systems, particularly where durability, leak-proof performance, and resistance to rust and chemicals are essential.Q: Where can these fittings be installed outdoors?

A: Thanks to their UV resistance and non-corrosive nature, SWR pipe fittings are perfectly suited for outdoor installations, including rooftop rainwater drainage, boundary drainage systems, and exposed waste lines.Q: What are the main benefits of choosing uPVC SWR pipe fittings?

A: Benefits include high durability, non-corrosiveness, lightweight handling, chemical and UV resistance, maintenance-free operation, and compliance with stringent IS standards, ensuring long life and reliable performance.Q: How do the surface finish and design improve system efficiency?

A: The smooth surface finish minimizes friction losses, allowing for more efficient flow and reducing the risk of blockages, while the leak-proof rubber ring sealing ensures system integrity during operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS